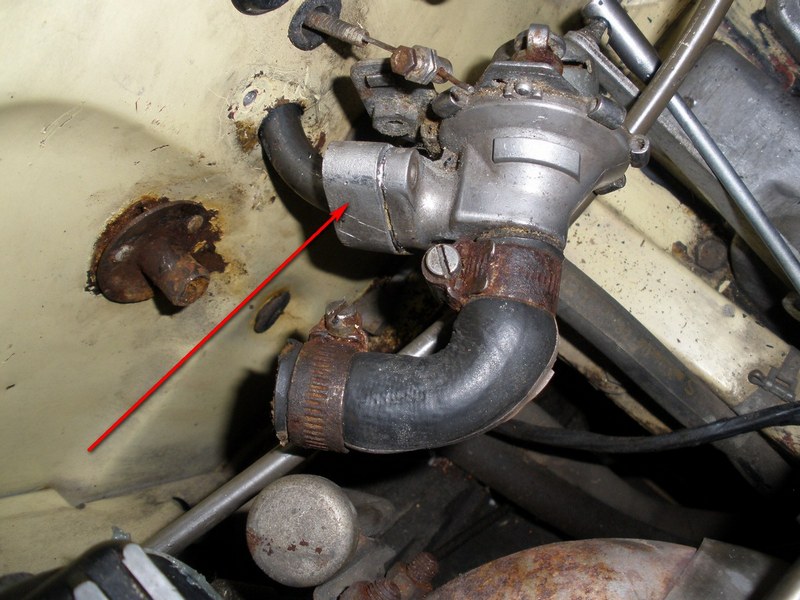

I'm restoring my '71 E FHC Series II and am working on the water pipes that are behind the firewall. The feed pipe (#35 on the heater components diagram) from the water control tap (#32) connects to the tap via a mounting block (#33) - see image below - but modest twisting pressure won't free the pipe from the inlet on the mounting block. I don't want to ruin the pipe by twisting harder but I can't figure out how the mounting block is attached to the control tap on one end, and the pipe on the other.

Any help here is appreciated.

Submitted by NC98-56048 on Mon, 01/06/2014 - 07:04

Submitted by reachafw@hotmail.com on Sun, 01/05/2014 - 16:07

HeaterComponentReplacements

Question #2 today Heater water radiator

The bottom plate (above) didn't seem to have heavy damage for a box that's been unopened or repaired for all these years, and there is no signs of dripping or flow beneath the box on the chassis. The first thought though is that the water came from a leak in the radiator inside the box (pic). I filled it with water and blocked one orifice, then blew as hard as I could into the other orifice, simulating as much internal pressure as I could. There was no sign of leakage, but I'm not sure if this approach would discover a small leak (as when the whole system is under pressure).

What are your recommendations to properly measure/pressure test the heater radiator?

Thanks, as always.

Tony

Submitted by reachafw@hotmail.com on Sun, 01/05/2014 - 15:50

HeaterComponentReplacements

Question #1 today - Rusted Bottom plate

Heater box is all disassembled. In good shape except for the bottom panel. This picture shows how rust has eaten away at it over the years. The rest of the box is very good. I found a place that makes duplicate bottom panels but wonder if there's an easy way to get the bottom panel off. It looks like it's spot welded on three sides and soldered in the corners. I there an easy way to get this off or do I have to find a metal works guy who probably routinely drills the spot welds off and removes the solder?

Tony

Submitted by NE23-54945 on Sat, 01/04/2014 - 09:49

HeaterComponentReplacements

Don't over think this, its very straight forward, if you are over 40 take plenty of advil for the finger swelling, but its not that difficult just another etype pain in the ......

Yes replace ALL the pipes, they are 40 plus years old....Its all about the rust.....

gtjoey1314 GOOD LUCK....

Submitted by NC98-56048 on Sat, 01/04/2014 - 09:07

HeaterComponentReplacements

Tony; You can't have enough pictures when you are redoing a car or working on parts of it. Since my car has a automatic transmission I can't help with the clutch problem but have a couple of suggestions but feel free to reject any or all.

There is a site,

http://www.jag-lovers.org/snaps/ . When I first started with my restoration I spent a day looking at as many different photo album submissions as I could stand. Some are well captioned and some not so well but they will be helpful. For example here is a listing for my heater box work.

http://www.jag-lovers.org/snaps/snap_view.php3?id=1291826761 . There are many good pictures on almost every aspect of the Jag.

There is also a illustrated parts book available that Richard Liggitt compiled and his email site is

Hope this helps and feel free to ignore any and all and you may know all this already. There are many on this site and the j-l site more knowledgeable and smarter then I. Good luck, Joel.

Submitted by reachafw@hotmail.com on Fri, 01/03/2014 - 10:08

HeaterComponentReplacements

Joel,

I havenÔÇÖt been able to find the schematic for the crossover pipe in the Bentley handbook. Looking at the firewall, I can see where the vacuum reservoir hose enters the firewall, and then back out on the drivers side of the engine. Since itÔÇÖs a ÔÇ£dryÔÇØ line for air, is there any specific need to replace it when IÔÇÖm installing new water pipes? And thank you for the cautionary comment of not forging ahead without thinking. ThatÔÇÖs why IÔÇÖm enclosing pictures where I can. I hope IÔÇÖm not including too many pictures. If so, let me know.

Craig,

I got the clip opened up and separated the motor armature from the wiper assembly. Now the question is ÔÇ£how to remove the wipers from inside the enclosure?ÔÇØ I saw one video (John Carey) where the armature bar that holds/connects the 3 wipers is disassembled from the actual wiper rods and then the wiper rods are installed, one at a time (because he notes he couldnÔÇÖt get the assembly in as a unit). The Bentley book says to remove the spindle housing after taking off the glove box and pull the whole unit out in that direction. IÔÇÖll try the Bentley approach unless someone out there indicates it wonÔÇÖt come out as one unit.

Ed. Note: As most of you already know, my ÔÇ£simple clean-it-upÔÇØ car project is quickly turning into a complete refurbishment (not ground-up restoration) on a car that hasnÔÇÖt been driven for over 10 years. One thing is leading to another. The water pipes situation led to removal of the heater box yesterday, which showed small rusted holes in the bottom of the box. IÔÇÖll need a new bottom place.

Next, the bottom-most water pipe attaches to a hose leading into the engine, just to the left of the intake manifold on LHD cars. Since I donÔÇÖt have an instrument to access and remove (then install the grommets in that small space), it looks like IÔÇÖll have to take the intake manifold off to work on the securing flange.

Next, I pressed on the clutch pedal and it went halfway to the floor and stopped... moved freely from the top to that stop point, but no farther. Looks like no fluid in the reservoir, so I need to start understanding whether the (empty) slave/master cylinders causes the pedal to lock halfway down to the floor. I canÔÇÖt imaging that the clutch release bearing is just stuck.

QUESTION - So all this doesnÔÇÖt get unmanageable, I think I need to start or find threads on each of my new projects (eg. ÔÇ£heater box, clutch, etc., etc.)? All your advice will be most helpful.

Thanks in advance.

Submitted by NE23-54945 on Tue, 12/31/2013 - 20:04

HeaterComponentReplacements

George brings up some good points.....When I did my total restoration, the replacement pipes were a hair off due to the more modern plating so they didn't rust. I also remember drilling out everything and pop riveting new flanges.

Get the wiper motor out of the way and find the family member with the smallest hands......

Once done you wont regret it, but its a pain at first. I had my pipes cad plated to prevent all types of issues.....

John Farrel out of new York still reproduces the set.

Good luck....

GTJOEY1314

Submitted by SW03-47225 on Tue, 12/31/2013 - 18:19

HeaterComponentReplacements

Hi Joel.

Be careful removing the clip, although Xks Unlimited do have them but they are $20 each. To remove the female part of the ball joint gentle light the pointy end of the triangle that is on each end of the spring. lift it until it is 90 degrees to it present position. It will be somewhat stable in that position. Do that to each en of the spring. This pulls the spring away from the ball and will let the female end to be removed without any resistance. Don't lose control of the female end. Carefully move each triangle back to its initial position before letting go of the rod, that will help to retain the clips. You may want to tape the ends. Installation is the reverse of removal, move the to triangle to the 90 degree position, place the female end over the ball, and then move the triangles back to lock in place.

Good luck,

Craig

Submitted by NC98-56048 on Tue, 12/31/2013 - 17:58

HeaterComponentReplacements

Tony; The vacuum crossover pipe will probably be with the brake system diagram as it serves to connect the vacuum reservoir on the right side of the car with the vacuum booster on the left side of the car ( if your car has a vacuum booster and is LHD) . The pipe is smaller in diameter then the water crossover pipes and is near 41 in your picture.

And yes that is the clip. I mentioned it as the posters on the J-L site mention it and apparently some have broken it and find it is missing after trying to get it apparatus out. I would hate to recount all the things I have messed up because I forged ahead before thinking.

As an aside I replaced all of my pipes, I am doing a complete restoration, and # 28 on the diagram seemed too long and I had to increase the bend that was already there then it fit perfectly. This is probably more then you wanted to know. Good luck, Joel.

Submitted by reachafw@hotmail.com on Tue, 12/31/2013 - 09:56

HeaterComponentReplacements

Joel,

The second question relates to the "spring clip". Is this the clip?

Submitted by reachafw@hotmail.com on Tue, 12/31/2013 - 09:54

HeaterComponentReplacements

Joel,

I have 2 follow-ups for you. I don't know how to send two pictures in the same message, so this will be 2 messages. First, I'm not familiar with the "vacuum crossover pipe. What number on this drawing is the vacuum pipe?

Submitted by NC98-56048 on Mon, 12/30/2013 - 22:55

HeaterComponentReplacements

Tony; As long as you are going to replace the water cross over pipes you might as well replace the vacuum cross over pipe as well. I think they are available in SS as well as normal steel. You are correct that the wiper mechanism has to come out first. Be careful as you remove the spring clip that holds the wiper mechanism to the wiper motor pin as it has a way of flying away and replacements are not available I am told.

Good luck. Joel.

Submitted by reachafw@hotmail.com on Mon, 12/30/2013 - 17:56

HeaterComponentReplacements

Craig & George,

I got the mounting block away from the control tap and the pipe is indeed rusted into the tap. Since I need to replace the pipes, I'll just cut the pipe off outside the firewall and see if I can break it loose on a vice. I suspect that the pap needs to be replaced and if so, I'll order that as well.

Many thanks you two!

Submitted by SE98-32482CJ on Mon, 12/30/2013 - 16:11

HeaterComponentReplacements

Tony that is the right approach. While the pipe may "flush" it is the drip, drip, drip inside the car that is the issue.

Submitted by SW03-47225 on Mon, 12/30/2013 - 16:09

HeaterComponentReplacements

Hi Tony, The pipe is a slip fit into the mounting block. There is a fat o-ring that goes around the pipe and is compressed when the mounting bolts are cinched up. I suspect that the reason it is on so tightly is rust.

Craig Wright

Submitted by reachafw@hotmail.com on Mon, 12/30/2013 - 13:26

HeaterComponentReplacements

Many thanks, but are you saying that the mounting block is just a sleeve that fits over (maybe tightly) the feed pipe and the pipe is swedged into an opening in the water control tap? Otherwise, if the pipe stops somewhere inside the control mounting block, how is the block attached to the tap?

Re: damaging the feed pipe. Actually, if you flush fit the mounting block to the firewall, the other end comes back out the other end, perfectly. The other one in the picture is pretty bad, so I'll take your advice and replace all three once I get them out (which I understand requires removal of the wiper control system... a very difficult task!)

Submitted by SE98-32482CJ on Mon, 12/30/2013 - 12:29

HeaterComponentReplacements

They are swedged together--they should come apart. From the photo you have already damaged the feed pipe. From the looks of the other pipe it is time to put a new set in the car. Sorry!

Tony; #1. If the rest of the heater box is good take it to a 'welding shop' and talk to them. They should be able to cut out the rusted piece and weld in some 20 gauge steel to replace it then you can paint it with rust inhibiting paint. That way you still have the original attach points and air diversion port. If you are able to weld you can do the repair yourself.

#2. Take your heater core to a radiator shop and ask them to test it, if solid ask them to clean it, if it isn't repairable then you will have to get a new one.

Joel.